- Author:

- Source: MW Associates

- Date: 2023-01-12

- Views: 1125Times

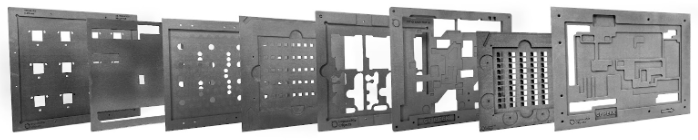

Wave solder pallets and high temperature fixtures support the mass manufacturing process of printed circuit boards, resulting in tremendous cost benefits. They reduce setup time, improve solder flow, reduce bridging and solder skipping, eliminate labor intensive hand masking, reduce board warping and protect heat-sensitive components.

Pallets and fixtures require machining and skilled labor to produce. This traditional production process can be slow and expensive. Impossible Objects’ revolutionary Composite Based Additive Manufacturing (CBAM) is breaking that paradigm.

Impossible Objects 3D prints wave solder pallets and fixtures using carbon fiber reinforced with high temperature PEEK polymer. These materials provide excellent thermal and chemical resistance for the wave solder process. Impossible Objects customers report that its pallets withstand thousands of cycles without material degradation or warping.

SMT China magazine launched the SMT China Vision Awards in 2007 to recognize both international and domestic providers of SMT equipment, materials, software and services that have made outstanding contributions to the rapid growth of China's electronics manufacturing industry by their inventions and innovations.

To learn more about Impossible Objects, visit www.impossible-objects.com.

###

About Impossible Objects

Impossible Objects is a 3D printer and materials company pioneering advancements in the additive manufacturing and composites manufacturing industries. Based on years of research and development, the company’s composite-based additive manufacturing technology (CBAM) is an entirely new process that is fundamentally different from conventional additive manufacturing technologies. To learn more, visit www.impossible-objects.com.

版权所有 ©深圳市亚中咨询有限公司

电话:0755-25856945 邮箱:pzl88smt@126.com 网址:www.smt668.com

地址:深圳市罗湖区怡正发大厦 SMT专业网版权所有(c) 2010 粤ICP备17073069号