- Author:

- Source: MW Associates

- Date: 2024-03-16

- Views: 1570Times

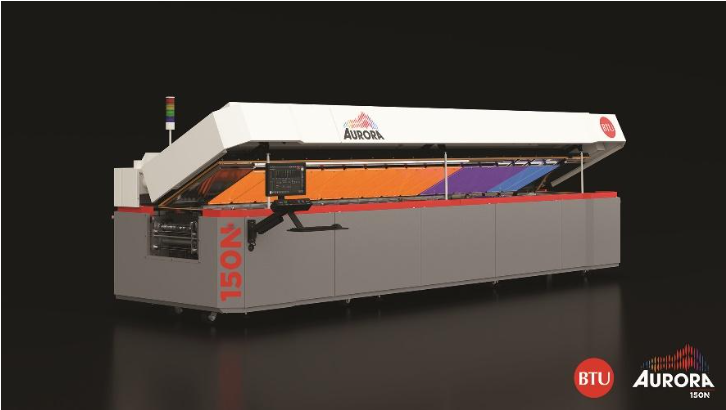

Aurora is guiding the way to the lights out Industry 4.0 factory of the future by seeing reflow in a new light. Using the combination of newly integrated process control technologies and innovative WinCon 8 software updates Aurora, consistently provides overall thermal process performance.

Implementing the industry’s first factory configurable heating and cooling zones provides the flexibility to customize your reflow oven for specific product/process characteristics including very heavy boards, slow cooling constraints, or increased throughput requirements. The Aurora platform is currently available in two powerful options, the Aurora 150N and Aurora 200N.

The new Aurora 200N is the longest and most advanced reflow oven ever produced by BTU. This groundbreaking addition to the Aurora platform sets a new standard for performance, flexibility and innovation.

“Aurora reflects our dedication to providing cutting-edge solutions leading the way to the future of reflow in a new light” said Rob DiMatteo, General Manager, BTU International. “Aurora was introduced in Europe in 2023 and we’ve been pleased with how well it’s been received. We’re excited to introduce the Aurora platform to the US market at APEX 2024.”

Alongside the Aurora 150N, BTU International will also feature the PYRAMAX 125 Air model. Manufactured with precision in Mexico, the PYRAMAX 125A exemplifies newly implemented onshoring initiatives. This approach is designed to mitigate supply chain risks by leveraging pre-established facilities with skilled labor.

The process maintains stringent quality control standards to meet customer requirements, all while reducing shipping costs and lead times. The PYRAMAX 125 Air incorporates advanced features such as closed-loop convection control and the Wincon 8 oven control system, ensuring superior performance and reliability within a compact footprint.

To learn more visit www.btu.com.

About BTU International

BTU International, a wholly-owned subsidiary of Amtech Group (Nasdaq: ASYS), is a global supplier and technology leader of advanced thermal processing equipment in the electronics manufacturing market. BTU’s high-performance reflow ovens are used in the production of SMT printed circuit board assemblies and in semiconductor packaging processes. BTU also specializes in precision controlled, high-temperature belt furnaces for a wide range of custom applications, such as brazing, direct bond copper (DBC), diffusion, and sintering. BTU has operations in North Billerica, Massachusetts, and Shanghai, China, with direct sales and service in the U.S.A., Asia and Europe. Information about BTU International is available at www.btu.com.

###

Company Contact:

Rob DiMatteo

General Manager

BTU International, Inc.

Phone: +1- (978) 667-4111

Media Contact:

Megan Wendling

MW Associates

Phone: +1-(239) 530-8790

版权所有 ©深圳市亚中咨询有限公司

电话:0755-25856945 邮箱:pzl88smt@126.com 网址:www.smt668.com

地址:深圳市罗湖区怡正发大厦 SMT专业网版权所有(c) 2010 粤ICP备17073069号