- Author:

- Source: MW Associates

- Date: 2025-03-14

- Views: 1088Times

Essemtec introduces new machine models enhancing pick-and-place speed with FOX Ultra and PUMA Ultra

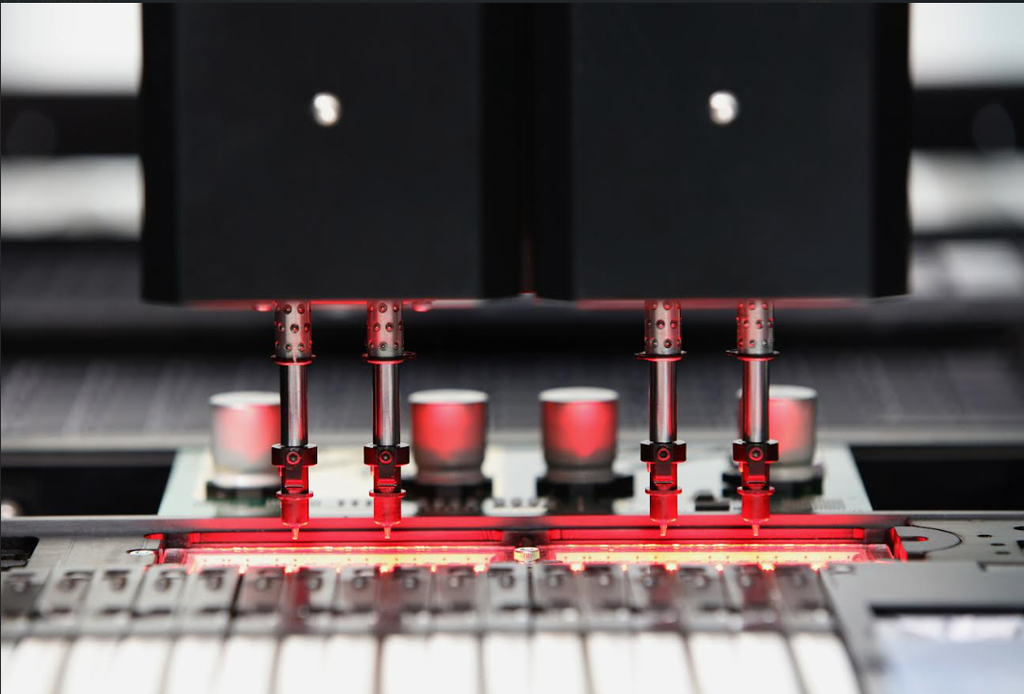

Essemtec is introducing two new pick-and-place machine models, the FOX Ultra and the PUMA Ultra, offering significant speed improvement compared to the world-renowned FOX and PUMA equipment.

New Performance and Speed

The FOX Ultra and PUMA Ultra deliver significant placement speeds enhancement, with the FOX Ultra reaching an optimum speed of 31,000 components per hour (CPH) and the PUMA Ultra achieving 30,000 CPH. These machines are designed to maximize efficiency while maintaining Essemtec’s renowned precision, flexibility and versatility.

Key features

- Optimum speed of 31,000 CPH (FOX Ultra) / 30,000 CPH (PUMA Ultra)

- Full range of components from 008004 imp (0201) up to 109 x 87 mm

- Full Traceability software package as standard

- High feeder density: 260 (140 inline) for the PUMA / 180 (120 inline) for the FOX

- Large variety of feeder solutions: loose component solution, stick feeder, strip feeders, tray changer, bowl feeder…

- Nonstop production Feeder Change over the All-in-One version is available to add dispensing and inspection capabilities

Versatility Across a Wide Component Range

Both machines support a full range of components, from the smallest 008004 imperial (0201 metric) chips to large components up to 109 x 87 mm. This broad capability ensures manufacturers can tackle a diverse set of assembly challenges with a single, adaptable platform.

Enhanced Traceability and Smart Software Integration

Both the FOX Ultra and PUMA Ultra are equipped with a full traceability software package as standard, ensuring complete process control and compliance with industry quality standards. This feature is essential for industries such as automotive, medical, and aerospace, where component-level tracking is critical.

High Feeder Density for Maximum Productivity

To accommodate high-mix production environments, Essemtec offers the highest feeder density of both machines:

- PUMA Ultra: Up to 260 feeders (140 inline)

- FOX Ultra: Up to 180 feeders (120 inline)

This high feeder density allows for seamless production of complex boards, reducing setup times and maximizing throughput.

Comprehensive Feeder Solutions

Essemtec continues to offer a wide range of feeder solutions to support various production needs, including loose component solution, stick feeders, strip feeders, and tray changers amongst others. These options ensure that the FOX Ultra and PUMA Ultra remain highly adaptable to evolving manufacturing requirements.

Nonstop Production with Feeder “Hot-Swap” Changeover

The FOX Ultra and PUMA Ultra feature Nonstop Production Feeder Changeover, allowing operators to replace feeders without interrupting the production process. This ensures continuous operation, minimizes downtime, and enhances overall manufacturing efficiency.

All-in-One Variant with Advanced Dispensing and Inspection Capabilities

For manufacturers requiring high-precision dispensing capabilities, the FOX Ultra and PUMA Ultra are also available as All-in-One variants. These models integrate Essemtec’s advanced dispensing technology, including High-Speed Solder Paste Jetting with Jet-on-the-Fly. This solution achieves impressive speeds, capable of jetting to an average of 280,000 dots per hour on standard boards and nearly 500,000 dots per hour on BGA patterns. Furthermore, Inspection capabilities guarantees highest quality demands. The All-in-One variants further extend Essemtec’s commitment to flexibility and efficiency in electronics manufacturing.

A New Era of Performance and Flexibility

With the FOX Ultra and PUMA Ultra, Essemtec reinforces its commitment to delivering cutting-edge technology that combines speed, precision, and flexibility. These next-generation machines empower manufacturers to optimize their SMT assembly processes while maintaining the highest levels of quality and efficiency. The IPC Hermes and CFX are also supported to ensure a seamless integration into any factory environment. These next-generation machines push the boundaries of speed, precision, and versatility, making them the ultimate choice for high-mix electronics manufacturing.

Grow Over Time with Multiple Machines Inline

Essemtec’s modular approach allows manufacturers to scale their production effortlessly. The FOX Ultra and PUMA Ultra can be seamlessly integrated into inline configurations, enabling a smooth transition from single-machine operation to a high-performance production line. Additionally, existing machines can be upgraded with advanced features, ensuring that customers can enhance their capabilities without the need for complete system replacements. Whether adding more machines for increased throughput or upgrading individual units to meet evolving production demands, Essemtec provides a future-proof solution for growing businesses.

“We are thrilled to introduce the FOX Ultra and PUMA Ultra to the market,” stated Olivier Carnal, General Manager of Essemtec. “These machines represent a significant advancement in our portfolio, reinforcing our commitment to delivering high-performance solutions that empower our customers. With enhanced speed, flexibility, and smart software integration including regular free software updates, we continue to support our customers in optimizing their production processes and achieving greater efficiency.”

For more information about the FOX Ultra and PUMA Ultra, contact Essemtec today by visiting our website www.essemtec.com or seeing a live demo of the Ultra at IPC APEX EXPO or Productronica Shanghai.

版权所有 ©深圳市亚中咨询有限公司

电话:0755-25856945 邮箱:pzl88smt@126.com 网址:www.smt668.com

地址:深圳市罗湖区怡正发大厦 SMT专业网版权所有(c) 2010 粤ICP备17073069号